Aquagga: Success Story

Awardee – FORGE Supply Chain Disruption Grant

PFAS (Per- and Polyfluoroalkyl Substances) pollute drinking water, wildlife, and the environment. The Environmental Protection Agency (EPA) has found these synthetic compounds in humans, animals, fish, water, and soil all over the globe. Aquagga’s mission is to eliminate PFAS, whose other claim to fame is that they do not break down over time, earning them the title, “forever chemicals”.

PFAS compounds repel water, making them ideal for their former role in “non-stick” Teflon cookware. PFAS commercial uses include: industrial coatings, water-proofing for clothing, firefighting foam (especially for highly flammable substances such as petroleum and jet fuel) and common lubricants. The EPA regulates some PFAS compounds, and tracks and tests contamination in riverways, surface water, soil, and groundwater. However, they are still calculating the effects of PFAS on human health.

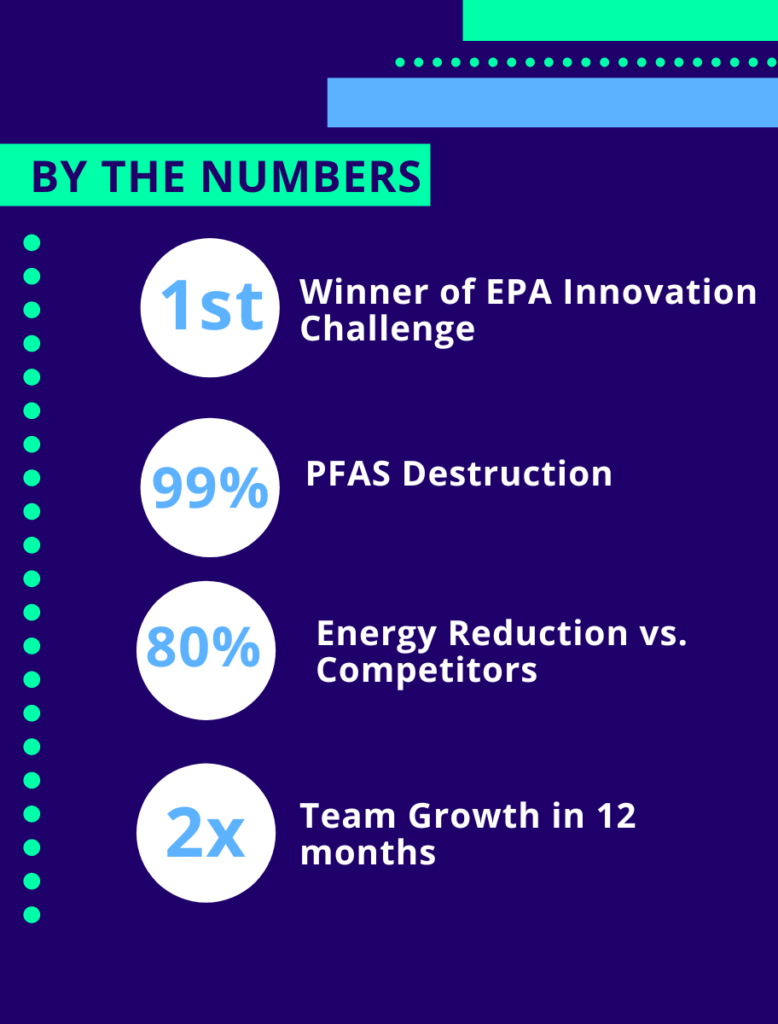

Some technologies can remove PFAS from water but leave residual material that must be incinerated (not environmentally sound) or encapsulated and buried (an expensive fix for a “forever” pollutant). Aquagga has developed an award-winning technology to safely and effectively destroy PFAS chemicals in water and other waste streams. No secondary remediation is required.

Brian Pinkard (CTO), Chris Woodruff (COO), and Nigel Sharp (CEO) founded Aquagga as a public benefit “Zebra” company, dedicated to integrating technologies and building collaborative solutions. Their name combines the Spanish word for water (Aqua) and an extinct subspecies of African zebra (Quagga), whose contrasting coat is a symbol of fusion. The company’s founders have roots in the University of Washington and the University of Alaska. They have completed seven accelerator/incubator programs with ongoing projects in Washington, Wisconsin, and Alaska, including the Arctic Innovator Program funded by the Department of Energy.

Chris is charged with developing partnerships and resources and tackling the elevated task of “getting things un-stuck.” The FORGE Product Development Grant came along at precisely the right time, when “stuck” became part of the pandemic supply chain vocabulary.

According to Chris, “Readiness is hard to sustain when you are simultaneously scaling both research efforts and manufacturing. We were leaping from development in milliliter test tube volumes, to gallons of water flow per hour. Carefully constructed budgets and operating plans, developed 6 months in advance, can quickly go off course with the scarcity of just one key component. FORGE understands startup trajectories, and the challenges of supply chain disruption. The FORGE Product Development Grant is injecting funds at a crucial time for us to continue to scale our technology to tackle a global challenge. FORGE resources and expertise are multipliers that have helped us keep everything in motion.”