AtlasXomics: adding a new dimension to gene regulation research

Transformative product blends epigenomics and pathology to unlock new discoveries

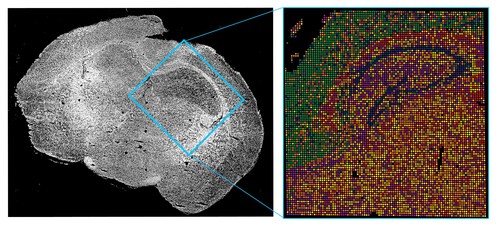

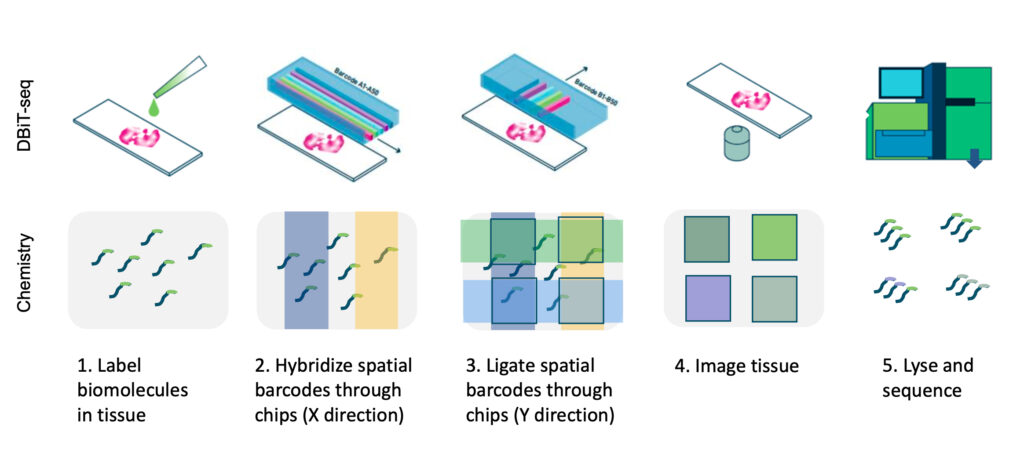

Your cells are constantly responding to your environment, your age, and your life experiences. While these changes do not alter your DNA, they do influence how your genes behave. Understanding these changes helps researchers make discoveries that lead to better medical tests and treatments. Connecticut-based startup AtlasXomics developed the FlowGel platform to let researchers see these gene-regulating changes exactly where they occur within tissue, where they matter most.

Early success, growing demand

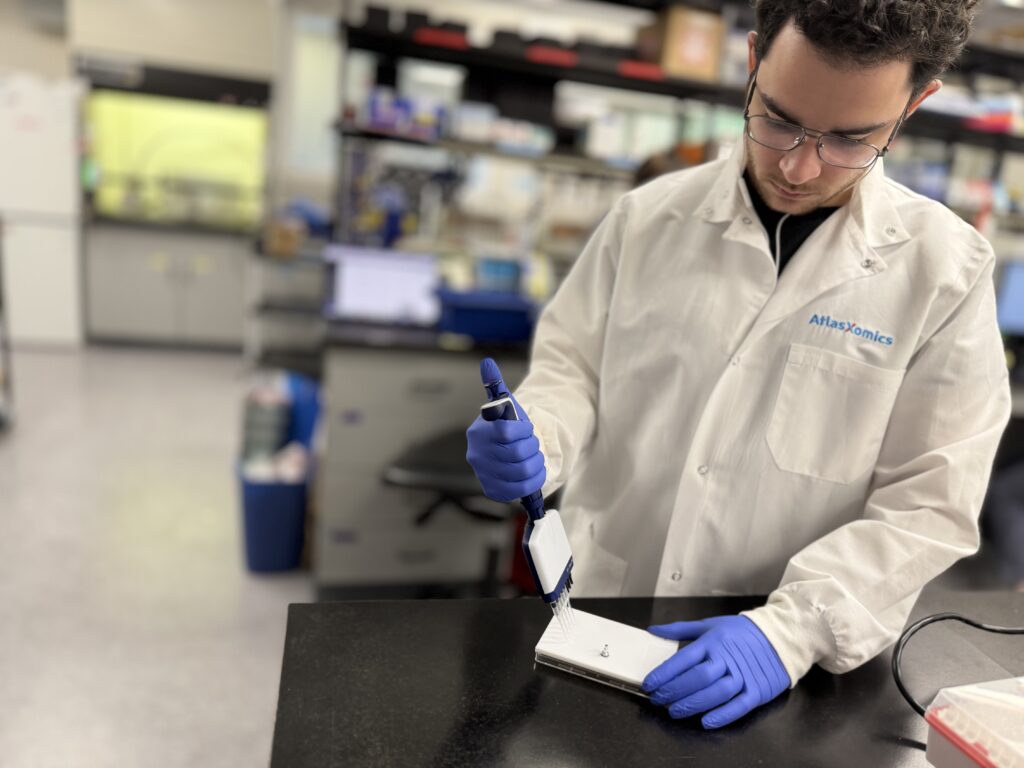

AtlasXomics’ FlowGel platform uniquely enables this type of gene-regulation mapping while keeping it accessible to everyday research labs. Unlike traditional approaches that rely on expensive, specialized hardware, FlowGel is a consumable-based system that lets researchers work within their existing lab setup. It delivers detailed, wide-area views of regulatory changes with less hands-on time and fewer opportunities for error, opening a powerful new modality to labs that previously could not access it.

Founded in 2020, AtlasXomics introduced its first epigenome-focused product in 2022 and has since grown to support more than 100 research labs, including teams at Yale University and the Broad Institute. Interest in the platform continues to expand as scientists apply it to better understand the biology underlying conditions like brain tumors, Alzheimer’s disease, and prostate cancer.

When AtlasXomics approached FORGE in 2024, it had a significant order backlog. The company was facing a familiar struggle for hardtech startups – finding a way to effectively scale up manufacturing while maintaining rigorous quality standards. AtlasXomics was looking to scale production from 10-15 units a week to 100-200, while improving the platform’s throughput and lowering its production cost. Keep in mind, each FlowGel device requires more than 400 manual pipetting steps, and the process can be vulnerable to dust contamination. Since the platform works at microscopic resolutions, quality standards were non-negotiable.

AtlasXomics’ effort was driven by rapidly growing demand for spatial biology and epigenomic tools. The global spatial omics market, a category that includes technologies for mapping biological molecules in their native spatial context, is already valued in the hundreds of millions of dollars and projected to expand to well over $1 billion by the end of the decade as research adoption accelerates worldwide.

FORGE’s impact

To meet this tall order, AtlasXomics needed a manufacturing partner that could meet its technical needs and quality standards. FORGE introduced the company to CPS Fluidics, a Connecticut-based microfluidics manufacturer. The two companies are just 18 miles apart – a true local manufacturer partnership.

AtlasXomics applied for a FORGE Product Development Grant to improve its manufacturing readiness, fund its collaboration with CPS Fluidics, and reach more research and development milestones.

FORGE selected AtlasXomics as one of its grant winners and awarded the company $70,000 in nondilutive funding supported by the Connecticut Manufacturing Innovation Fund. With that funding, AtlasXomics has:

- Completed a full redesign of its platform

- Integrated critical improvements to boost throughput

- Optimized its platform’s manufacturability to prepare for scale

- Placed its first full prototype order with CPS Fluidics

Colin Ng, AtlasXomics’ vice president, said “The updated design is expected to significantly improve both throughput and manufacturability. We’ve just ordered the first full prototype and plan to begin initial testing in February.”

The testing is AtlasXomics’ next step on its journey to commercialization and driving impact in spatial biology and advanced life sciences research. With funding, right-fit connections, and manufacturing readiness expertise, FORGE was instrumental in helping AtlasXomics reach this milestone.

Moving forward: expanding AtlasXomics’ offering and market

With this MIF-funded FORGE Product Development Grant, AtlasXomics and CPS Fluidics are partnering to scale the manufacturing of FlowGel and accelerate the company’s next phase of growth. This collaboration will enable a far more scalable production process, greatly increasing throughput and allowing the platform to reach many more laboratories. As FlowGel becomes easier to produce and distribute, researchers will be able to run larger and more ambitious studies, accelerating discoveries across basic and translational epigenomics, medical research, and the broader life sciences.

At the same time, AtlasXomics continues to expand its scientific capabilities with new products and research efforts, including tools that work with archived tissue samples often used in clinical studies. The team is also developing technologies that capture multiple layers of information from the same piece of tissue, from how genes are regulated to which genes and proteins are active, helping researchers connect the dots and gain clearer insights. Together with the state-supported manufacturing scale-up, these innovations will make the FlowGel platform even more transformative for labs around the world while driving continued economic growth in Connecticut.

By the numbers

- More than 100 labs using FlowGel

- $14.5 million in raised capital

- $70,000 in non-dilutive product development funding from FORGE