florrent: Success Story

Carbon-sequestering ultracapacitors bolster electrification

To understand why ultracapacitors like the ones florrent makes matter for renewable power grids, imagine an average weekday. Between 5 and 7 pm, thousands of office workers in your city go home. When they get there, they turn on the lights and climate control, start cooking dinner, and start loads of laundry. In most places, the sun will already be setting, so solar power can’t meet the demand. Electrical grids must bring other power sources online in a hurry. Rapidly drawing electricity from a battery can shorten its lifespan, but ultracapacitors can spring into action in seconds without damage.

So, florrent’s ultracapacitors support a green energy transition. But a material inside them helps fight climate change in a different way. florrent uses hemp, a carbon-sequestering plant, to make the activated carbon which gives its ultracapacitors their, well, capacity. Activated carbon can be made from many types of plants, from coconuts to wood and peat moss. Hemp is a particularly sustainable option. The plant is fast-growing and regenerates soil by storing carbon and nitrogen in the ground.

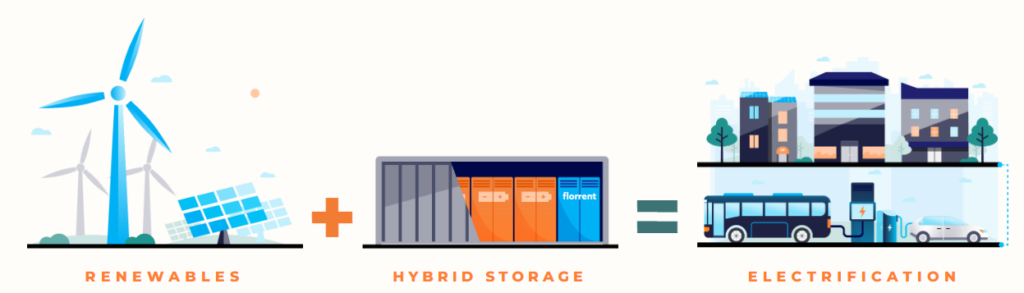

Since using hemp sequesters carbon and ultracapacitors support a renewable electrical grid, florrent’s product has the potential to keep a lot of carbon out of the atmosphere. Deploying florrent’s ultracapacitors alongside renewable generation resources like wind farms and solar panel arrays will make the power grid greener, more stable, and more equitable.

Green devices support the electrical grid using a hemp-based material

It all started when Jose LaSalle was a kid. From childhood, LaSalle was interested in engineering and inventing. Facing energy scarcity in his youth pushed him to focus on solving energy problems.

“I started studying engineering with the goal of inventing solutions for an equitable energy transition,” he said. “I knew since I was 16 or 17 that I wanted to be in this space. It was a really meaningful and exciting way for me to use my interest in engineering.”

LaSalle studied electrical engineering at UMass Amherst. He worked in research labs on materials synthesis. He worked at startups as an engineer. On nights and weekends, he developed the ultracapacitor technology that caught the interest of his co-founders, CPA Joe Hastry and engineer Alex Nichols. The founders named their startup florrent by combining the words ‘flow’ and ‘current’. The name represents their ultracapacitors’ ability to deliver a high-amperage flow of electrical current. It also refers to the idea of balancing and stabilizing the flow of energy.

LaSalle, Hastry, and Nichols established florrent in February 2020. The early COVID-19 pandemic was rough on most companies, but florrent weathered the storm. LaSalle lived in Oregon and was used to calling his co-founders in Massachusetts on Zoom. Investors shifted to Zoom, too, providing valuable opportunities for florrent to network. florrent was on a mission to regenerate soil, improve the electricity supply chain, and create a technically excellent, economically competitive solution for the energy transition.

Making connections to scale with FORGE

florrent is a member of Greentown Labs, which is where LaSalle first heard about FORGE.

“We got connected to David Thompson [FORGE’s Sr. Program Manager], who gave us two phenomenal connections which have been instrumental for our business: one for third-party testing for cells and one for expertise on techno-economic analyses.”

LaSalle said FORGE’s insight into florrent’s product and business helped them succeed. “FORGE had a very clear understanding of what gaps we had and were very fast and intentional about putting us in touch with the right people. I see clearly that it’s their goal to accelerate our development and commercialization path.”

florrent is far down that path, having nearly reached its commercial form-factor proof of concept. There are two elements to the proof of concept: the activated carbon and the ultracapacitor cells. florrent is already producing activated carbon from hemp on a small scale. It’s in the process of technologically and economically validating large-scale activated carbon production. florrent has a commercial design for the cells in which it uses the carbon. It will deliver a minimum viable product (MVP) for its customers – ultracapacitor OEMs and grid asset integrators/operators – to evaluate by the end of the year.

Looking forward

Over the next few years, LaSalle’s goals are to scale florrent up at a fast, healthy pace, fulfill current customers’ interests and bring on new customers. In the long term, he sees florrent’s ultracapacitors serving an important role in sustainably electrifying American infrastructure and supporting local economies.

He said, “We envision having factories to produce our cylindrical cells, selling them to enable continued and widespread adoption of renewables and helping to electrify our infrastructure. That will be in close connection with our supply network of farmers who are growing many thousands of acres, sequestering many tons of carbon, and bringing wealth into their communities. I want to see our rates of pollution go down and rates of prosperity go up.”