GenH: Success Story

The Next Generation of Energy

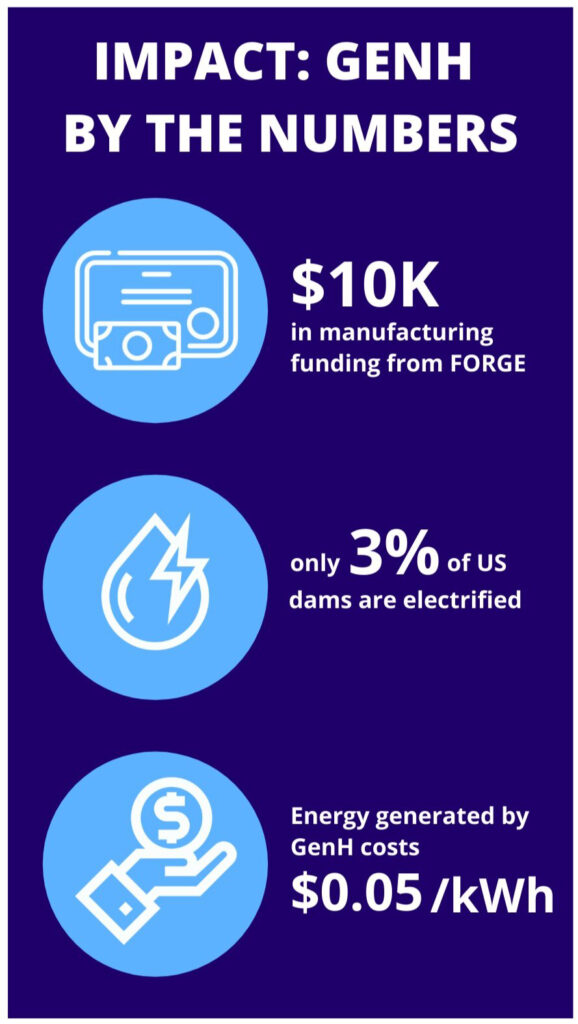

Founded in 2018, GenH is on a mission to redesign renewable energy systems. After completing his graduate thesis at the Gordon Engineering Leadership Program at Northeastern University, Co-Founder and Engineer, Siddharth Pannir, discovered a resource problem in the hydropower industry. Out of 85,000 US dams, only 3% are electrified, and on average, electrifying non-powered dams cost $400 million and take 7 years to build. Given society’s desperate need for stable renewable energy, these barriers were unacceptable.

Renewable energy needs a redesign

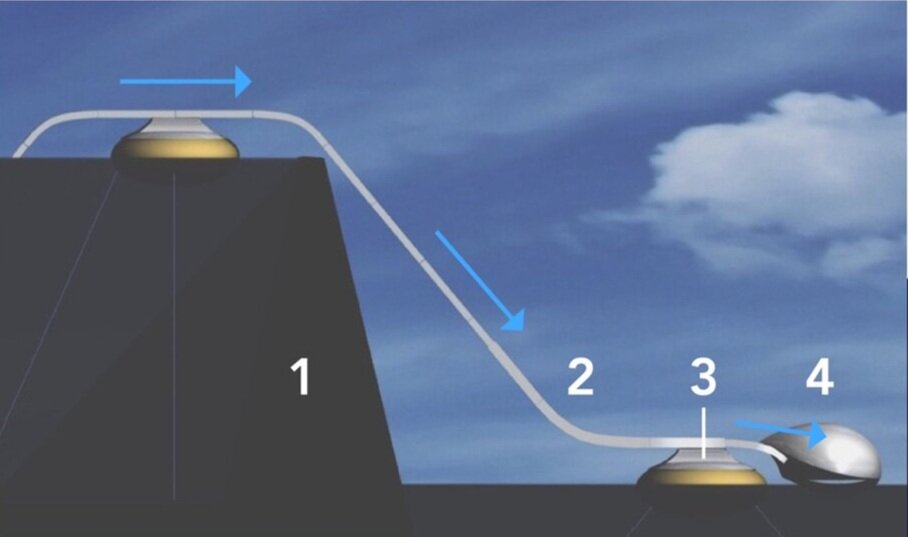

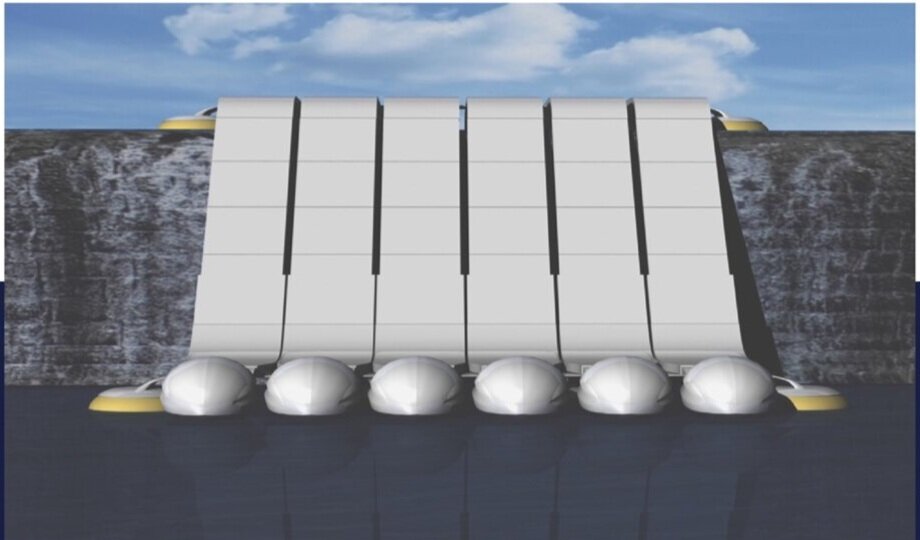

GenH believes rapidly deployable, resilient hydropower systems answer the calls for stable renewable energy. The GenH team has developed a way to optimize and streamline the energy generation process of dams – enter Adaptive Hydro™, a first in class, modular hydropower system that is designed to electrify non-powered dams and canal heads without construction or investment in fixed infrastructure. Adaptive Hydro™ technology side-steps the lengthy permitting processes and cost of traditional dam constructions. By siphoning the water of the dam from the top to the bottom and funneling it into the Adaptive Hydro™ system, it converts the flow of the water into electricity.

Adaptive Hydro™ is simply a better system design in terms of energy performance, resources necessary per megawatt, and economics. It is an easily deployed pumped-storage hydropower solution, making it highly adaptable to a wide range of scenarios. Adaptive Hydro™ even generates power at a cheaper cost than natural gas. It also has capabilities to ensure safe migration of fish and downstream oxygen and nutrient replenishment and temperature adjustment for better riverine environment health. GenH is changing the renewable industry by eliminating construction costs and producing stable cheap clean power without need for storage; thus, introducing modularity and mobility against the threats of resource and climate volatility to the market.

FORGE impact

“I feel very excited for this award, thank you to FORGE, and the entire team at FORGE, for going above the call of duty to help me prepare and win this award.”

— Siddharth Pannnir, Engineer and Co-founder, GenH

GenH first approached FORGE for assistance manufacturing a streamlined prototype that is faster, cheaper, and more sustainable. After connecting with a number of manufacturers in the FORGE network, GenH participated in the Product Development Grant Competition held at the Massachusetts Manufacturing Mash-Up – and won the grand prize of $10,000 in non-dilutive funding.

GenH is currently in the pre-commercial phase and intends to use the funds to expedite and modularize the manufacturing process, with a goal of optimizing the production process technically and economically. After streamlining their production, GenH plans to scale their manufacturing, rapidly deploying the product to initiate pilots across the country, like their existing one in Framingham, MA. The team plans to pilot their technology at dams, Squam Lake, NH, Merrimack Valley, California’s Coachella Valley irrigation district Palos Verde, and Imperial irrigation District with a timeline to release their product to market in 12-18 months.

FORGE looks forward to seeing the progress GenH makes over the next year, as well as continuing to support their impactful technology through regional manufacturing and supply chain connections. Congratulations, GenH!