Kuva: Success Story

Making the invisible measurable

Kuva Systems is looking at today’s global oil and gas market through a brand new lens – both literally and figuratively. Using an IoT solution to monitor and quantify the amount of methane and volatile organic compounds (VOC) emissions seeping out of faulty equipment, Kuva is able to make visible the gas itself as well as the danger it poses to our society. The Kuva platform is helping reduce greenhouse gases by enabling energy companies to find and repair methane leaks quickly and automatically.

Kuva’s impact

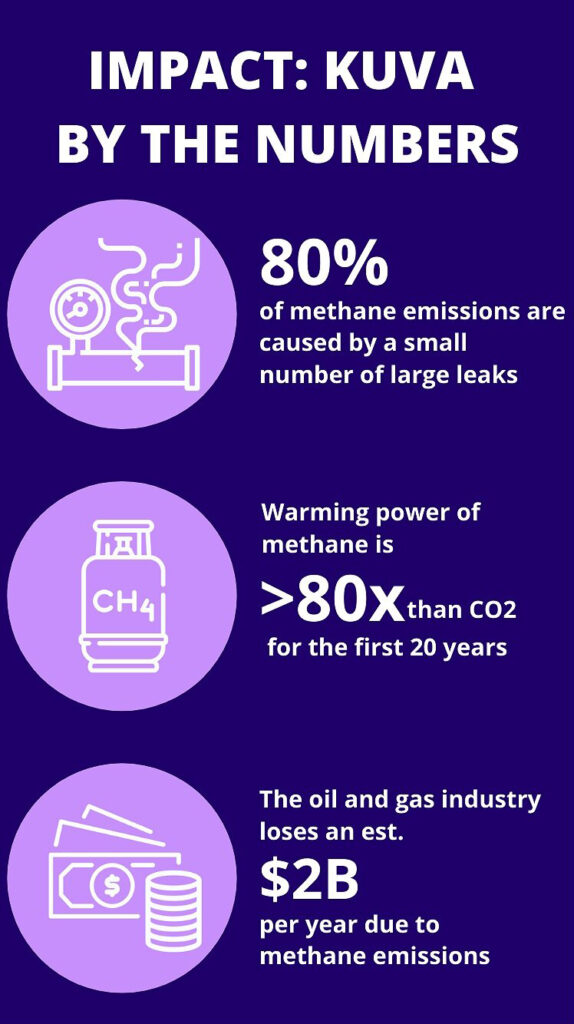

As a young systems engineer, Kuva founder Jason Bylsma recognized the flaws in the gas and oil industry’s methane leak detection. Despite being colorless and odorless, methane has more than 80 times the warming power of CO2 for the first 20 years it is in the atmosphere. According to the Environmental Defense Fund (EDF) , the US oil and gas industry emits about 13 million metric tons of methane/year. Globally, the climate impact of oil and gas methane is about as big as all CO2 emissions of the entire European Union.

A key contributor to these methane emissions is malfunctioning equipment. Kuva cites that approximately 80% of methane emissions are caused by a small number of large leaks from malfunctioning oil and gas equipment so it is critical to find and fix these leaks. Today, gas and oil companies only carry out in-person inspections about once-per-year. Thus, large leaks can go undetected for long periods of time. Bylsma and his business partner founded Kuva to prevent these oversights.

Kuva’s product

Kuva, whose name means “picture” in Finnish, provides a fully automated, image-based, continuous methane monitoring and quantification solution. Featuring a low-cost camera placed at oil and gas sites, the technology automatically detects emissions and quantifies gas flow rates based on minute-by-minute measurements. The pole-mounted camera works like a security camera, except it detects invisible gas. If and when a leak occurs, the site owner is automatically alerted and sent an image clip through Kuva’s cloud solution, visualizing when, where, and how much methane was emitted. The image is critical to enable site owners to pinpoint the leak and plan repairs accordingly. Users can set up custom alarms in the Kuva cloud to match their reporting preferences.

Environmental, Social, Governance (ESG) is driving oil and gas companies to seek out continuous Methane monitoring solutions such as Kuva Systems. Kuva’s Director of Mechanical Engineering, Terry Jones, explained that the financial sector is putting pressure on the gas and oil industry to measure, report and reduce their emissions. A brief glance at “Larry Fink’s 2021 letter to CEOs” shows that ESG is a force with which to be reckoned. Kuva enables the oil and gas industry to prove to investors that they are limiting Methane emissions, using a direct measurement, not an estimate.

“Buyers of imported natural gas in Europe and Japan, as well as an increasing number of gas utilities in the US, are looking to pay a price premium for natural gas that has been certified as being produced with low emissions.”

— Stefan Bokaemper, CEO

FORGE impact

After a successful funding round and growing to a team of 20 employees, Kuva has been on a hot streak. Thanks to a grant from Emissions Reductions Alberta (ERA) Kuva was able to install cameras in Canada. According to Jones, moving the cameras around to several dozen oil and gas production sites has been a great way to test and refine Kuva’s design. Over the past 6 months, the company has seen a wave of inbound inquiries from prospective customers, and recently closed its first commercial sale.

FORGE is proud to support innovative companies like Kuva Systems, and looks forward to watching their continued success and impact.