VesprSolar: Success Story

Making solar energy click

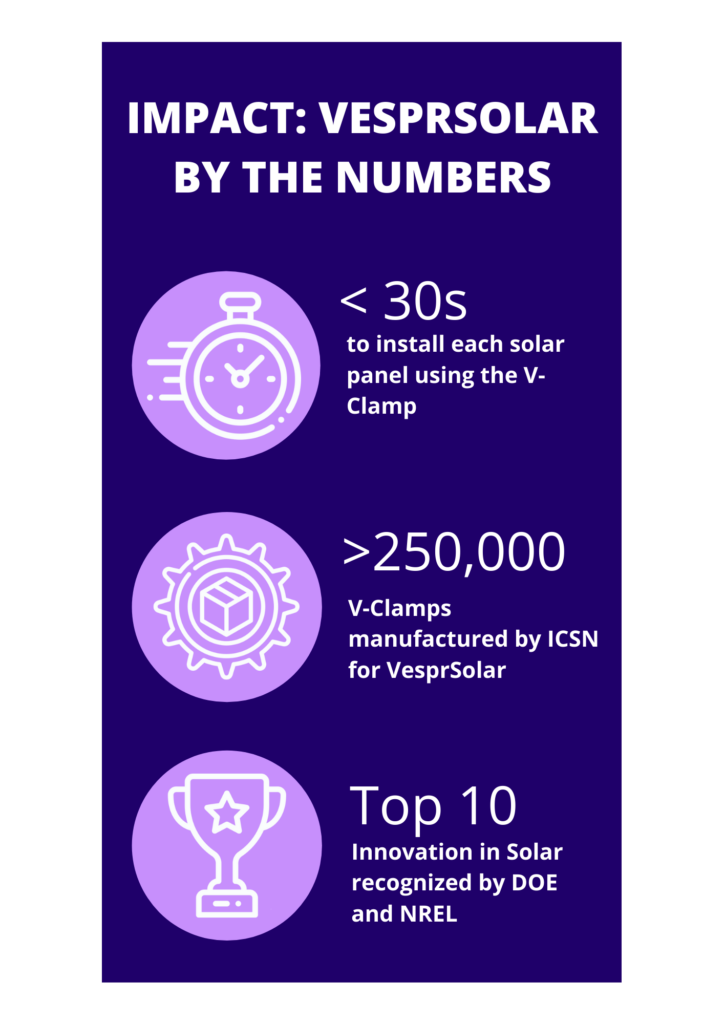

VesprSolar Impact

VesprSolar is helping make photovoltaic (PV) solar installation faster, cheaper, and more reliable with its breakthrough PV module attachment technology, the V-Clamp. With the U.S. solar industry experiencing an average annual growth rate of 42% over the past 10 years, VesprSolar’s innovations are helping support the rapid roll out of PV solar globally.

VesprSolar has over a decade of experience innovating on the PV installation process and developing solar racking components for utility-scale solar projects. VesprSolar’s core technology, the V-Clamp, is a two-time winner of the Department of Energy’s (DOE’s) American Made Solar Competition, recognized as a top innovation in solar by the DOE and NREL for 2020. The V-Clamp is now being deployed on large scale utility projects around the world.

VesprSolar was born out of research led by the University of Oklahoma. It maintains a close partnership with the university to develop next gen PV installation components.

The VesprSolar V-Clamp

Introducing the V-Clamp. The V-Clamp is a low-cost fastener used to secure a PV module to an underlying rail. The V-Clamp provides physical attachment and system grounding. Antiquated fasteners that are used today, such as bolts and bolted clamps, make PV module installation slow, increase direct labor costs, and can cause system failure. Bolts and bolted clamps have been identified as primary causes of PV failures in severe weather due to self-loosening and frequent installer error.

The V-Clamp is a fast-install alternative that eliminates bolted joints’ common failure modes. Each V-Clamp installs in less than 5 seconds, and a set of V-Clamps installs an entire panel in less than 30 seconds. The multi-functional product also easily integrates with leading solar racking systems. VesprSolar has worked with Sandia National Labs, UL, and the University of Oklahoma to conduct performance and reliability testing to prove that the V-Clamp meets the most rigorous site conditions for PV deployments globally.

FORGE Impact: Wielding Partners

FORGE’s connection between VesprSolar and ICSN significantly accelerated VesprSolar’s product commercialization timeline. As VesprSolar CEO Robert Sewell explained, ICSN helped VesprSolar setup the company’s entire supply chain. VesprSolar worked with ICSN’s engineering team to advance the V-Clamp from a prototype to a commercial-ready product. Sewell proudly called ICSN VesprSolar’s “most important partner” in the product development process.

“You can’t just Google ‘manufacturing abroad.’ First, you need to find the right person, and that process takes a lot of time. The fact that [FORGE] has a curated list, made the process so much faster.”

— Robert Sewell, VesprSolar CEO

Sewell insisted that startups need to make sure they partner with a manufacturer who is the right fit for the company. To bring a product to market, startups need support in many different areas. Does the manufacturer have the right capabilities that your startup needs at that moment? What type of relationship do you want your company to have with your manufacturer? These are two of the many questions that factor into choosing the right-fit.

Securing the Future

What’s up next for VesprSolar? Well, Sewell cannot reveal all of the company’s exciting plans, but he assured us multiple projects are underway with top name solar companies. In fact, VesprSolar will have shipped more than a quarter-million units by summer’s end! VesprSolar is working on expanding its product-line to address all attachment applications in the PV market.

At FORGE, we are ecstatic, but not surprised, about VesprSolar’s accomplishments. VesprSolar and ICSN make a winning duo, and FORGE cannot wait to cheer on this match as they continue to streamline the solar panel installation process.