Innovating Through COVID-19: Why Localizing Your Supply Chain Is More Important than Ever

Key Benefits of Securing and Diversifying Your Supply Chain During COVID-19

Image courtesy of Treasury & Risk

Global supply chains are being radically disrupted by COVID-19. Innovative companies are navigating these changes, and in some cases pivoting to help in the fight against coronavirus. Securing and diversifying supply chain and hardware-friendly funding is crucial for your business as you navigate through this public health crisis.

At FORGE, we help with our Manufacturing Initiative and a supply chain network that includes hundreds of manufacturers and suppliers who are locally-based and excited to work with innovative companies like yours. Over recent weeks, we’ve been in touch with many who remain in operation – and ready to help design and create your products!

Localizing and Diversifying Supply Chain Is More Important Than Ever for Risk Mitigation

In a report released in March by the Institute for Supply Management (ISM) – the world’s largest supply management organization, with over 47,000 members in 90 countries – the ISM found the following:

-

75% of companies are seeing supply chain disruptions currently. (Source: Supply and Demand Chain)

-

95% believe that their business will be impacted.

-

Lead times for inputs have more than doubled.

-

Manufacturing capacity abroad has been nearly cut in half. (Source: Institute for Supply Management article published in Baker City Herald)

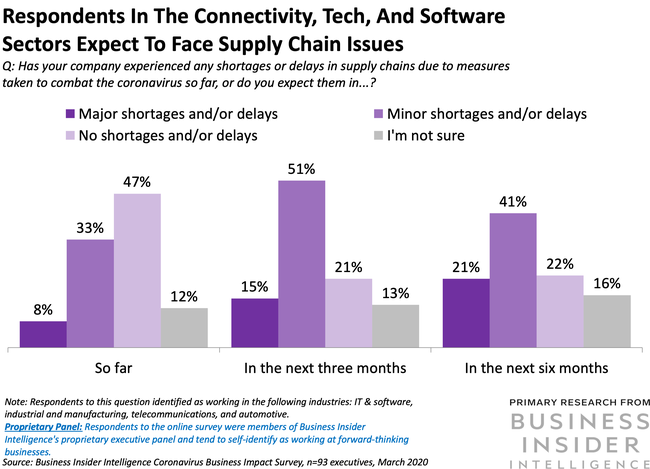

With most respondents anticipating increased severity of impacts through Q2, the effects of coronavirus aren’t limited to startups alone. Even massive, multinational corporations have felt the squeeze of COVID-19. Business Insider reports that companies once thought virtually immune to disruptions like this, like Samsung, are reporting shortages and delays throughout their supply chain (Source: Business Insider).

Image courtesy of Business Insider Intelligence.

Even before COVID, the future trend of supply chain localization was projected by major industry research looking 50 years forward (Source: Industry Week). With global production disruptions from COVID-19 in dominant geographies like China, innovative companies are turning to local supply chain growth opportunities now more than ever.

At FORGE, we’ve long seen the advantages to the startups we work with of sourcing regionally. Localization helps streamline and create efficient communication and development processes, and in many cases helps to protect IP and build strong relationships, providing advantages to innovators who manufacture close to home. Additionally, manufacturing locally reduces associated costs and carbon footprint from overseas shipping, which can be significant with heavy cargo.

How We Help Through Our Manufacturing Initiative

FORGE is here to support you as you adjust and grow – specifically with manufacturing readiness and supply chain connections.

Engaging with FORGE starts with answering a 5-minute on-boarding survey and is followed by a call with a program manager. These initial conversations allow our team to quickly assess current product development and supply chain needs – and to offer additional preparatory value. We provide the support needed to effectively engage with manufacturers, before making right-fit introductions to our network so that startups get a speedy response and the opportunity to review competitive bids.

This process has been refined and improved based on the support of hundreds of startups and years’ of unique data. After offering initial support, the FORGE team follows up to check the success of our recommendations, track progress, and help with any new supply-chain needs. 75% of the startups we have helped return with new requests in the future as they scale and their supply chain needs evolve.

If you are a manufacturer yourself, make your own parts, need supply chain help or want to aid in the face of this public health crisis, explore our new page of resources below.

Navigating COVID-19 Disruptions for Startups

BioBot – A global leader in wastewater epidemiology, Biobot Analytics is currently testing sewage samples from wastewater treatment facilities across the US to test for SARS-CoV-2. This data will be a critical addition to existing patient testing data to measure the scope of the outbreak and guide a community’s response. Read more in Biobot’s Success Story.

How We Help

Most recently, FORGE has connected BioBot with two Massachusetts-based corrugated manufacturers, Rand Whitney and Commonwealth Packaging, that have remained open, offering second source options after their original supplier closed.

In addition to assisting Biobot and their innovative work, FORGE has already supported over 70 startups in 2020. At least 12% of the startups that FORGE has worked with in the past month specifically cited COVID-driven disruptions to their business. As we’ve now explicitly added this question to our intake process, and as the crisis persists, we anticipate this percentage accelerating.

How the FORGE Supply Chain Network is Contributing to the Fight Against COVID-19

Image courtesy of Tech Crunch, showing a factory that has pivoted to making masks for COVID-19.

Beyond our continued work supporting Biobot, FORGE currently has almost 20 separate in-network efforts related to COVID-19 response to PPE and ventilator alternatives. This number continues to grow everyday.

For example, early efforts to help UMASS procure die cutting capabilities brought to light an opportunity for another member of the FORGE supply chain network, Pioneer Packaging, to design and distribute medical face shields to their channel partners. Mark Scagliarini, VP and General Manager said “We took the base concept and made it manufacturing-friendly. Without this introduction from FORGE, Pioneer may not have recognized the role they could play in helping fight COVID-19!”

FORGE’s Origin & How You Can Access Our Network and Help

The Manufacturing Initiative was built at Greentown Labs – the largest cleantech incubator in North America – in 2015, in response to the needs of the dozens of startup members community, with the goal of helping to solve the hardware-specific challenges of strategizing and scaling manufacturing. This is accomplished by providing support and curated connections to regional supply chain partners – help we know you may need now more than ever!

FORGE (formerly Greentown Learn), the nonprofit sister organization of Greentown Labs, was created to execute the impactful Manufacturing Initiative. Today, FORGE continues to execute on-mission: to help startups on the journey from prototype through to commercialization at scale.

Manufacturing Initiative Office Hours with the FORGE Supply Chain Network and investors most relevant to our startup community continue in a virtual capacity until further notice. Sign-up here for office hours with the experts and be on the lookout for additional virtual programming coming soon, or contact the FORGE team with your manufacturing and supply chain needs.