Manufacturer Perspectives: Why You Should Work With Innovators

Startups and manufacturers are drivers of the local economy, and when they collaborate they can accelerate bringing leading-edge technologies to market together, with talent attraction and business growth benefits for the suppliers. However, there are barriers of perception and of lack of supporting tools that can prevent these fruitful collaborations. Startups often assume they must outsource overseas, despite the strength of the manufacturing network available locally, and many manufacturers are wary of engaging with potentially unprepared or unscalable startups.

To understand both the benefits and drawbacks of working with innovators or startups, we spoke with Mark Tabor of Samtec and Chris Carlin of ICSN, both manufacturers with a strong regional presence that partner with FORGE to work with new products and early-stage companies to develop and scale their production. ICSN Group is a global product development firm with a branch office right here in Massachusetts that specializes in design for manufacturability, engineering, and contract manufacturing. Samtec is a global manufacturer of connectors, cables, optics, and RF systems and a service leader in the electronic interconnect industry, with a location in Westford, MA.

Both companies have worked with FORGE to help innovators manufacture their products at meaningful scale. Since first partnering with FORGE in late 2018, Samtec has worked with dozens of startups, providing essential components – and even pro bono product advice and select components at no cost to FORGE startups. ICSN officially partnered with FORGE in early 2020, and has already been connected to nearly 30 startups and sponsored our first Mechanical Design Challenge. Read on to see their perspectives on the unique competitive advantages that working with startups presents by adapting to a changing industry, diversifying their portfolios, and entering the innovation ecosystem.

Adapting to a Changing Industry

Recent years have exposed the manufacturing industry’s big PR problem – it is greatly disconnected from the fast-paced, diverse, and modern startup culture that makes up a large part of the untapped labor market. College graduates and young engineers flock to startups for exciting opportunities and to engage with cutting-edge businesses. According to research done by Deloitte and the Manufacturing Institute, 2.4 million open positions in the US manufacturing industry are vacant due to a skills shortage. Working with and highlighting innovative and cutting edge products is an underutilized way to reinforce what the manufacturing of today and tomorrow looks like, and attract young technical talent.

Reaching this emerging demographic has been a big learning curve for Samtec after an internal audit revealed the design engineers coming to their organization had a mean age of 47. To combat this, Samtec launched an entirely new business development function to reach millennials and new engineers. “It’s been an adjustment for us to cater our message in ways [younger engineers] will hear it,” Mark Tabor explains. Samtec began to build up its online presence, publishing relevant blog posts and sharing announcements through social media. This new initiative also included building strong relationships with organizations like FORGE, incubators, and local universities to educate the younger engineering community on Samtec’s products and services. These efforts have paid off: when sales for one of Samtec’s legacy products began to decline, they replaced that business with this brand new customer base.

Diversify Your Portfolio

In an unstable economy, a diverse portfolio is critical to any manufacturer’s long-term success. For many small to medium-sized manufacturers, just a handful of large companies represent a majority of their revenue, meaning that one lost client can be incredibly detrimental to their operations. We saw this play out during the COVID pandemic, for example, when sheet metal manufacturers were hit hard by a reduction in demand from the transportation industry. To mitigate risk, one way manufacturers can diversify their portfolios is by working with a number of smaller, but still well-prepared and funded startup companies.

As the Director of Business Development at ICSN, Chris Carlin estimates that 25% of their portfolio is represented by startups. “It’s exciting to work with people from the concept stage all the way to production,” he says. Mark Tabor, the Market Development Manager at Samtec, estimates that they have worked with thousands of companies less than a year old. In fact, their product lines are intentionally catered to smaller customers.

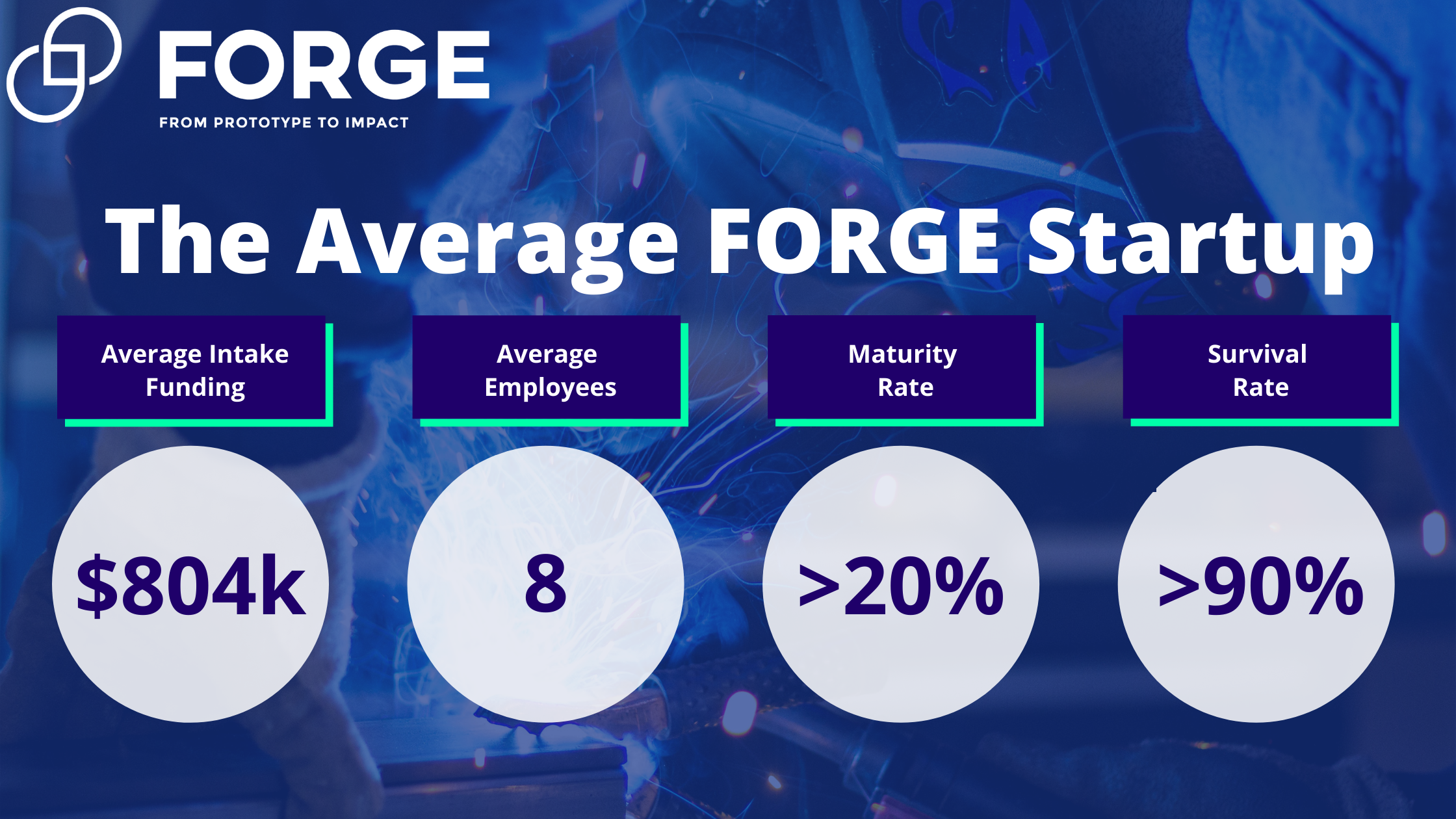

Startups are often stereotyped to be unprepared and underfunded – but the average FORGE startup is more mature and prepared than many assume when they hear the term “startup.”. To date, FORGE has supported over 375 startups with a current average of over $804,000 in intake funding and 9 employees. FORGE startups have a survival rate of over 90%, and 20% of the FORGE portfolio is “mature,” meaning they are prepared to begin low rate production. FORGE supports these startups to help identify key manufacturing needs and then make right-fit and meaningful connections to our network suppliers. Importantly, FORGE requires at minimum a looks-like or works-like prototype, as well as an appropriate budget for the supplier, before making introductions to suppliers in our network. One advantage, according to our suppliers, is that startups have far less bureaucratic approval requirements than larger organizations, creating a greater probability for a successful sale. Working with new innovations at an early stage may be daunting, but through engaging early and building a trusting relationship, you can help them grow into one of your biggest clients.

Enter the Innovation Ecosystem

Another benefit of engaging with startups is becoming a part of their network and entering the exciting and inspiring innovation ecosystem. Chris Carlin speaks fondly of this environment, “Our CEO Joon Lee has a soft spot for innovation and startups. We’re both small business owners and we appreciate the effort, ingenuity, and entrepreneurship they bring.” With less red tape and no shareholders to please, it can be refreshing to experience the higher energy, visionary thinking, and faster pace that startups can bring to your company. Mark Tabor disagrees with the common stereotype that startups are difficult to work with, going as far as to say he has found working with them more rewarding.

FORGE’s startup portfolio boasts an incredible survival rate of over 90%. According to our partners, even in the event of a startup’s failure, there is still an opportunity for the manufacturer, including return on investment in the form of the connections and relationships formed within the startup ecosystem. With engineers and designers bouncing between startups or eventually settling at larger organizations, you have the potential to create a lifetime customer. Mark Tabor brings up an interesting point, “Our larger competitors don’t support startups, they only want to be doing business with Dell, Google, or Apple. When we support startups from that early stage, we get a customer for life because they remember that connection.” With the right impression and giving startups a chance, you will have clients that keep coming back for your services for the rest of their careers, no matter where they are employed.

Getting Involved

Working with startups can help manufacturers attract new talent, prepare for Industry 4.0, diversify their portfolios, and reap network benefits from the innovation ecosystem. While it may be daunting to get started, our supplier partners have a few parting words of wisdom. Chris Carlin of ICSN highlights the importance of aligning your corporate culture and expectations in order to successfully work with startups. “We welcome these opportunities knowing that we won’t see a product or purchase order in six weeks. This is a marathon, not a sprint,” he explains. Product development is not an easy process, with constant iteration and prototyping in order to reach perfection. Good things take time, and your considerations as a manufacturer will be remembered by your clients.

Mark Tabor of Samtec urges other suppliers to understand the importance of their position. He self-declares his expertise to be at the bottom of the food chain for most of his clients, as engineers often don’t give much thought to connectors and cables when designing their products. However, he says, “I’m not just connectors, I’m 20+ years of experience in the electronics business that can help you on all your component and design issues. That’s the value of suppliers.” FORGE aims to create more than just a business transaction, and instead create a mutually beneficial partnership between suppliers and startups.

Our Supply Chain Network is composed of over 430 regional manufacturers, suppliers, design firms, and engineers who work with our startups to provide them the critical pieces they need for their physical products. FORGE ensures right-fit connections between our startups and our supply chain partners, mitigating any risk and ensuring a successful collaborative relationship from the start. We have made over 1,700 connections, which have resulted in over $30 million in known contracts and purchase orders. If you’re a manufacturer or supplier, learn more about our supply chain network and how to get involved! Join our sponsor network to gain unequaled access to our expansive network of over 375 startups to date.

If you’re a startup with a physical prototype looking to get connected to the supply chain, sign up for a Product Development Session!

Want to learn more about our connections and previous companies we’ve worked with? Check out our Startup Success Stories!

Looking for supplier expertise on common product development and manufacturing challenges? Check out our Tools of the Trade!