Mash-Up Took Manufacturers Out to the Ballpark

On a beautiful day at Worcester’s baseball stadium, Polar Park, manufacturers, startups, suppliers, students, and legislators met to celebrate manufacturing in Massachusetts.

To kick off the day, we presented a mixture of live remarks and recorded messages from Massachusetts leaders including Speaker Ronald Mariano, Senate President Karen Spilka, Secretary Mike Kennealy, Senator Eric Lesser and Representative Jeffrey Roy who lauded the manufacturing community for their hard work, innovative products and methods, and their resiliency.

While the Woo Sox (Worcester Red Sox) did not take the field, it was still a busy day at the ballpark. While manufacturers and legislators stood for applause during the morning’s caucus awards, 300 high school students from all over Massachusetts had fun with engineering games. They were hard at work in teams competing to create the most paper airplanes. These manufacturing exercises demand reasoning, the ability to follow a design, and teamwork. Oh, and the kids had a good time while learning a little about careers in STEM (Science, Technology, Engineering, and Math).

On the concourse, representatives from manufacturers, suppliers, and state organizations spoke with attendees about their products, methods, and missions. The following FORGE partner organizations had tables at Mash-Up.

-

MassMEP provides grants, training, and support for manufacturing in Massachusetts.

-

Alternative Manufacturing Inc (AMI) manufactures electronics, enabling a host of businesses to thrive. They’re based in Somerville, MA and Winthrop, ME.

-

Bossard is an international supplier of fasteners, clips, and welding supplies for industry with a local office in Stoughton, MA.

-

Burt Process Equipment supplies pumps and other fluid handling technology from their Camden, CT headquarters.

-

Cambridge Polymer Group tests, develops, and improves materials at their research facility in Woburn, MA.

-

Empire Group designs and creates products using a wide array of manufacturing processes including additive manufacturing and rapid injection molding at their Attleboro, MA facility.

-

Hypertherm Ventures invests in startups, entrepreneurs, and other innovative early-stage companies in advanced cutting, additive manufacturing, robotics, AI, industrial IOT, and advanced materials

-

New Page Associates enables startups to succeed with engineering support and investor analysis from ideation to prototype to production from their Arlington, MA office.

-

PEKO manufactures complex electro-mechanical machinery and equipment for industry in their Rochester, NY plant.

-

Plastic Manufacturing Resources (PMR), headquartered in Upton, MA, designs and fabricates plastic manufacturing products for injection molding, additive manufacturing, thermoforming, and more.

-

Product Resources provides design, engineering, and production for medical, life sciences, and industrial applications from their Newburyport, MA offices.

-

Samtec is a national supplier of cables, connectors, and RF equipment.

At FORGE’s Pitch Event, Laura Teicher, Executive Director of FORGE, talked about the innovative manufacturing ecosystem in Massachusetts and the value of bringing stakeholders together. She touted the startup scene for manufacturers in Massachusetts, saying, “FORGE will work with more than 300 startups this year, leading to the creation of innovative products, manufacturing relationships, and jobs.” FORGE Program Manager David Thompson then introduced the three finalists for the FORGE Product Development Grant. Judges Gavin Braithwaite from Cambridge Polymer Group, Ellen Ellsworth from MassMEP, and Jason Enos from Empire Group, took notes and asked questions of the founders before making their final decision.

The three finalists for the product development grant were:

Osmoses has created a membrane with applications for hydrogen separation and natural gas purification. Co-founders, Katherine Mizrahi-Rodriguez, Ph.D., and Holden Lai, Ph.D. discussed how their membrane could be used for carbon capture by fitting easily into present systems without the need for retrofitting.

rStream Recycling’s CEO, Ian Goodine described their robotic and data solution to the problem of separating recyclables. Starting with places like schools, concert venues, and sports arenas, Goodine hopes to show the ROI (return on investment) in correctly categorizing even 1% more recyclables.

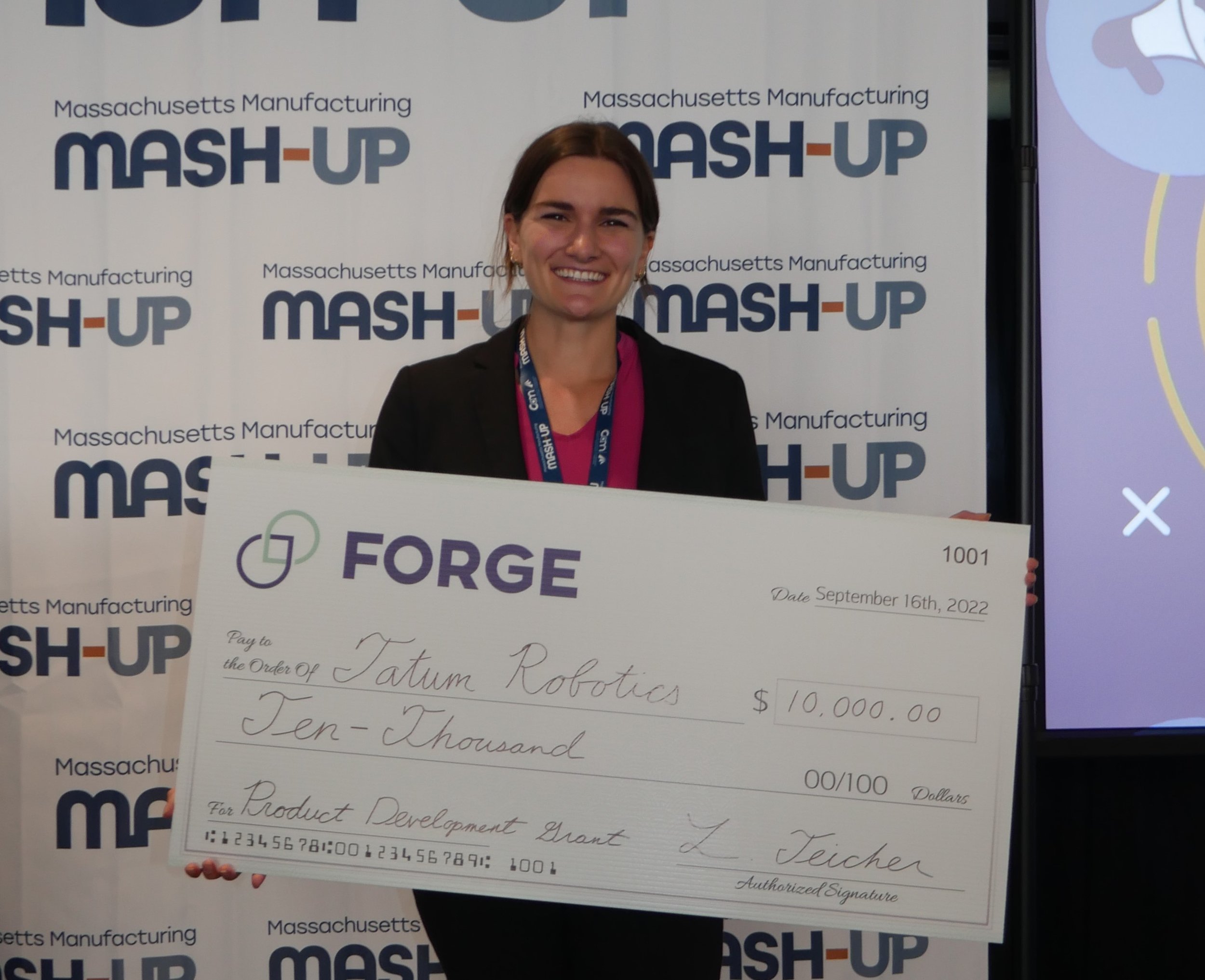

Tatum Robotics founder, Samantha Johnson and her team have created an articulated robotic arm and hand that deafblind people can use to communicate with others. Deafblind individuals use a tactile type of sign language and are often left out of the loop when it comes to news and information. Tatum’s goal is to produce these robotic arms to help disseminate information to the deafblind community.

From left to right, Holden Lai and Katherine Mizrahi Rodriguez of Osmoses, Samantha Johnson of Tatum Robotics, and Ian Goodine and Ethan Walko of rStream Recycling

All three teams captivated the audience, but the judges chose Tatum Robotics to win the $10,000 FORGE Product Development Grant. The on-site attendees were able to get in on the action too and helped to determine the winner of our $5,000 Audience Choice Award, rStream Recycling.

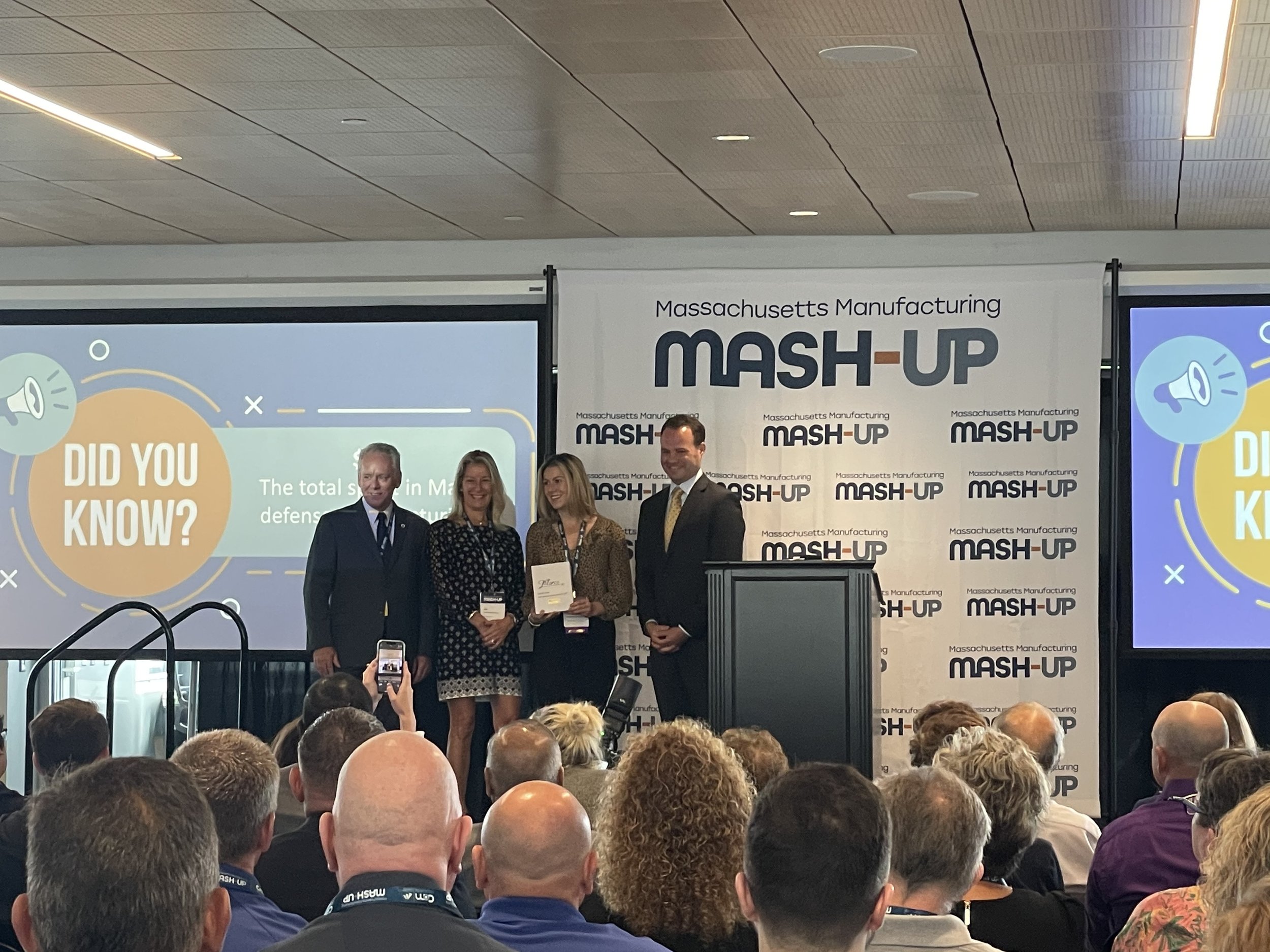

Christine Nolan, Director of the Center for Advanced Manufacturing, Kathie Mahoney, President & CEO of MassMEP, and John Regan, President & CEO of AIM (Associated Industries of Massachusetts) all spoke throughout the course of the day and praised the inventiveness and perseverance of Massachusetts manufacturers and businesspeople.

Senator Eric Lesser and Representative Jeffrey Roy presented regional manufacturing awards to manufacturers and startups manufacturing locally (with help from FORGE!) across the state. One company, Worthington Assembly of South Deerfield, has manufactured circuit boards and semiconductors since 1976. Another, Somerset Industries from Lowell, designs and builds professional grade equipment for bakeries and the foodservice industry. Springfield Spring and Stamping, a manufacturer of springs and wire forms, is also one of the largest certified minority- and women-owned businesses in the United States. Heila Technologies builds electrical systems from the ground up, reducing system complexity and cost while increasing ease of integration. There were over fifty companies nominated for awards by their local representatives. They won for creating new products and jobs, fabricating products locally for decades, or for pivoting during the recent COVID crisis to make masks and other protective devices for medical workers, first responders, and the public. The DCU Club was filled with colleagues, supporters, and well-wishers.

With all the Zoom calls and remote meetings of the last few years, it was great to get out on a sunny day and meet with the people who make Massachusetts work.